Deploy 95% faster with the Jacobi Palletizer

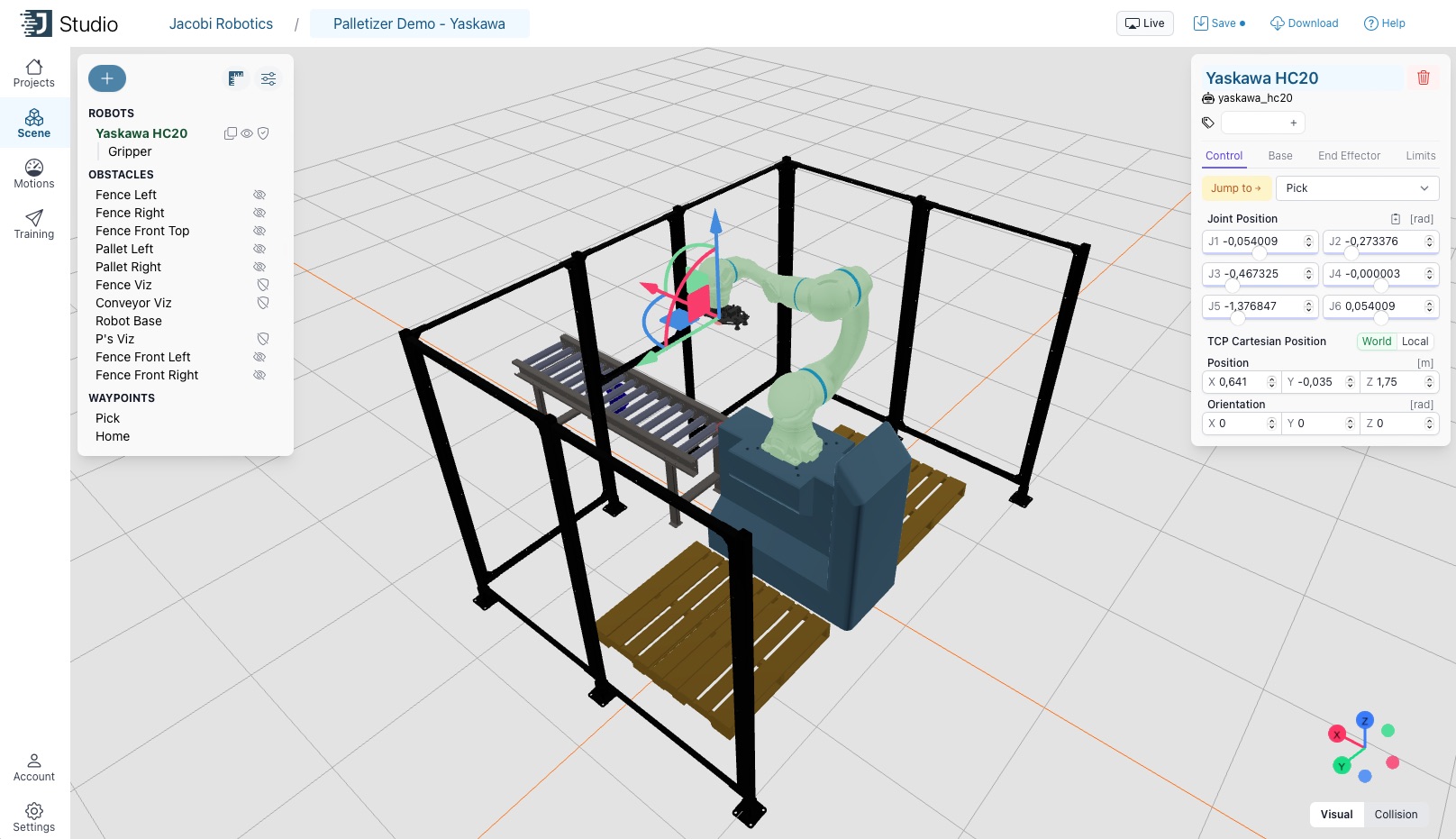

The Jacobi Palletizer is a software application designed to reduce the development and deployment time for system integrators. Set up a cell in hours, not days or even weeks.

Eliminate the need to manually teach robot paths with Jacobi's Motion Platform, allowing bold, fast, and optimized robot trajectories for the best cycle times.

Build with your preferred robot

Here's what you get

- WIN DEALS

30% quicker cycles

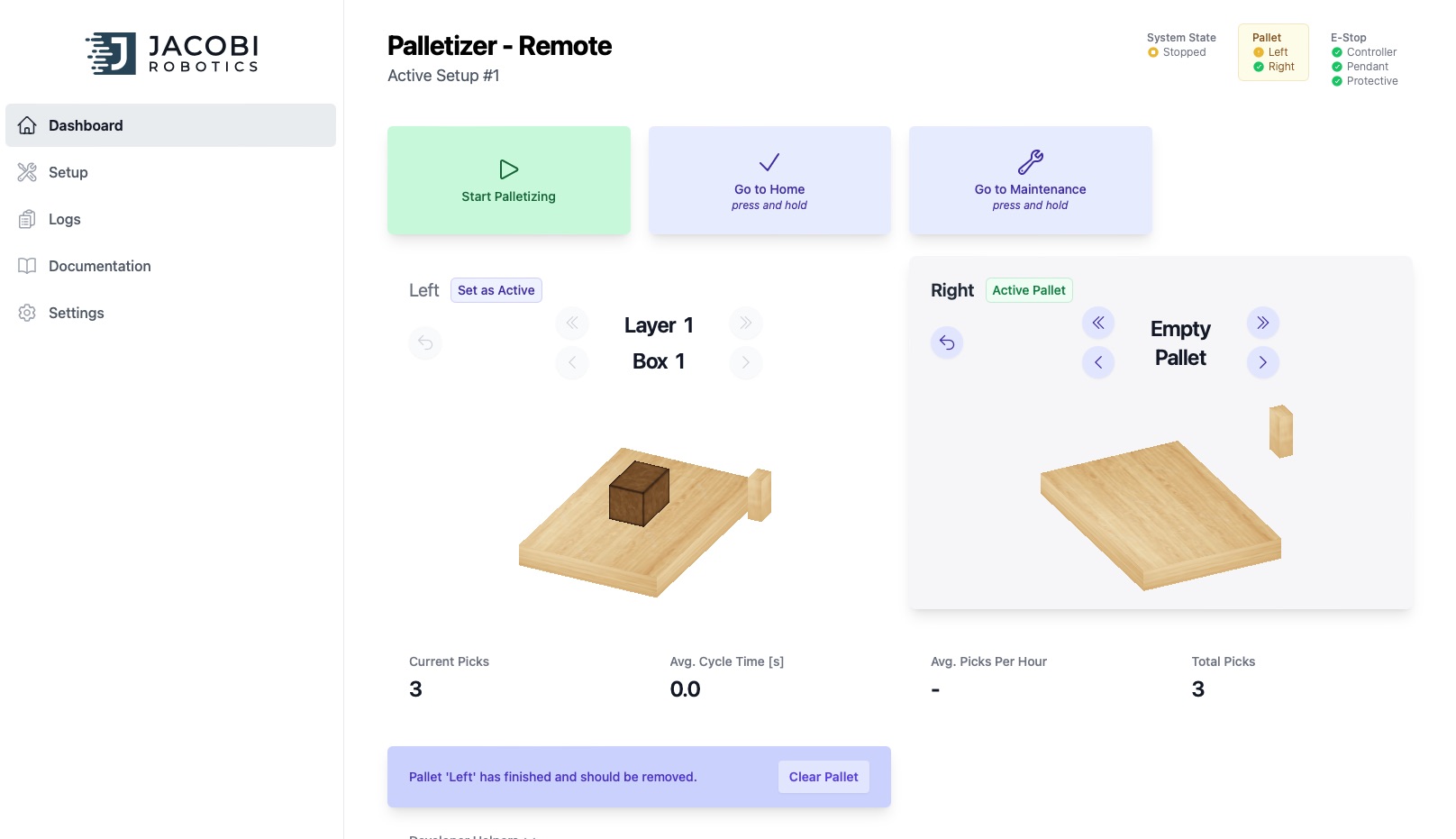

With the best cycle time and a live simulation to showcase to your customers, you'll have an unbeatable competitive edge.

- DE-RISK SAT

95% faster commissioning

Imagine programming robots without worrying about collisions or singularities. SAT becomes short and predictable.

- FAST UPDATES

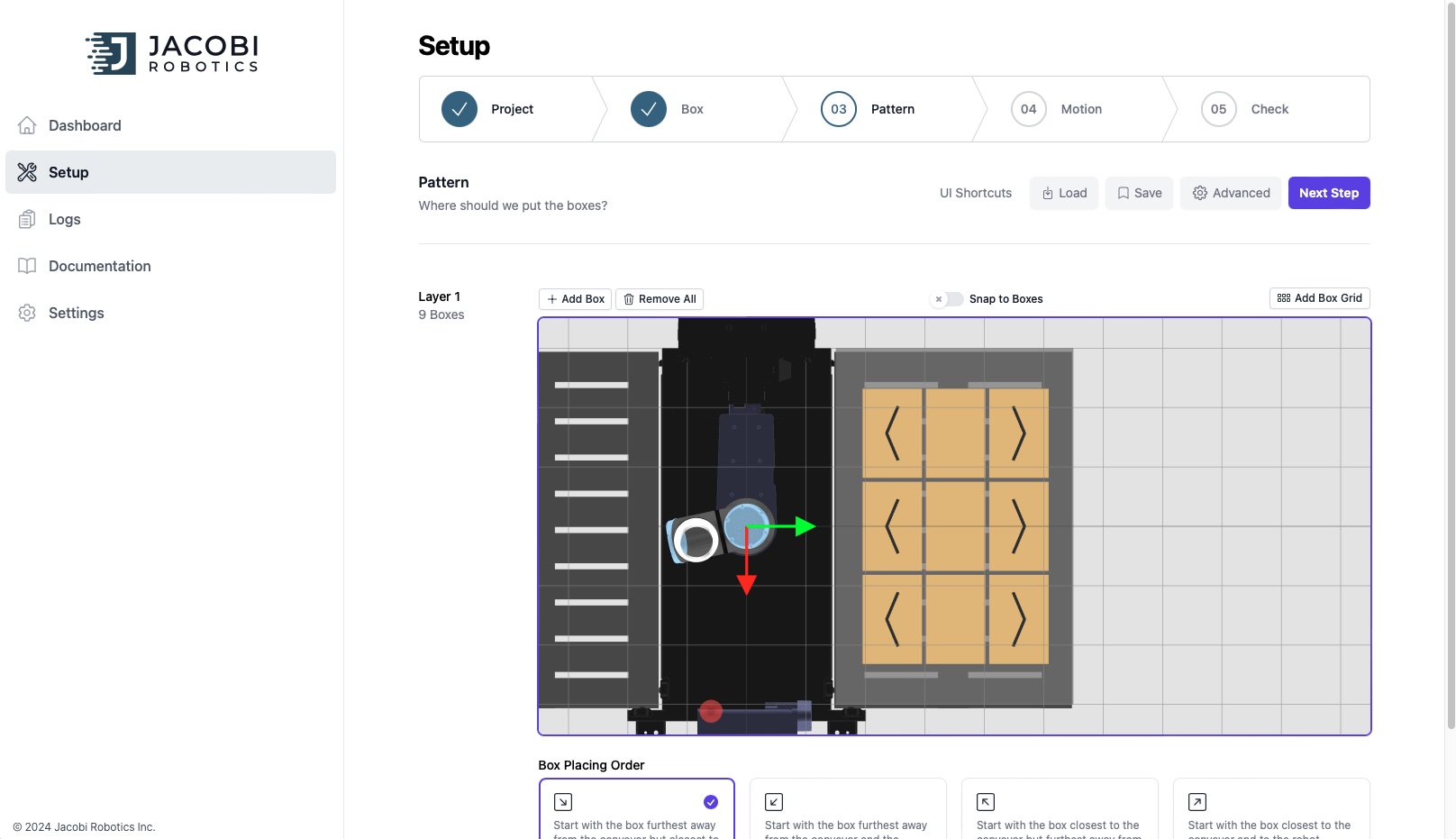

5 minutes / pattern

Post-deployment support is simplified with rapid pattern programming and real-time remote monitoring, streamlining production.

Learn how Formic reduced their SAT time by 95%

Join our email list to receive our case study and find out how Formic benefitted from short and predictable SATs.

.

Here's What our Customers Have to Say

Torfresma USA

"Jacobi's AI technology gives us a significant competitive edge by streamlining deployment and reducing manual programming. This partnership enables us to take on more complex projects while maintaining rapid delivery times, giving us more room to innovate and grow our business."

Read more about Jacobi and Torfresma USA

"Working with Jacobi, I've found their innovative palletizing software to be a game-changer. It stood out against the many other tools I evaluated throughout my career. It streamlines programming across different robots and hardware, enhancing deployment and remote operations, all make my work faster and more efficient. Jacobi is truly redefining industrial automation from my perspective."

Read more about Jacobi and Formic

Unlimited Electro

Unlimited Electro

"Jacobi Robotics has transformed our palletizing processes. Their innovative software integrates seamlessly with different robotic systems, making deployment quick and remote operations efficient. The intuitive interface has significantly reduced programming time and increased our productivity. Jacobi is a true partner in automation, and their palletizing solutions are top-notch. We couldn't be more satisfied."

Read more about Jacobi and Unlimited Electro

Feature Plans

The best Palletization solution,

for the best price

Jacobi Palletizer

Choose from a wide range of pre-set standard palletizers or customize your standard offer with the Jacobi Studio.

- 1 in 1 out or 1 in 2 out

- Optimized cycle time

- Single or double pick

- Slip sheet

- Customize hardware setup

- Remote monitoring

- Custom HMI

Jacobi Palletizer Pro

Let's work together to create a custom solution specifically designed to meet your unique operational needs.

- Multi in multi out

- Optimized cycle time

- Single pick, multi pick, multi-pick single place

- Slip sheet

- Barcode scanner

- Remote monitoring

- Custom HMI

- Vision-based pick validation

Let's Get Palletizing!

Robotics is hard nonetheless - that's why we support you with integration and custom use cases.

If you're interested, reach out to us!